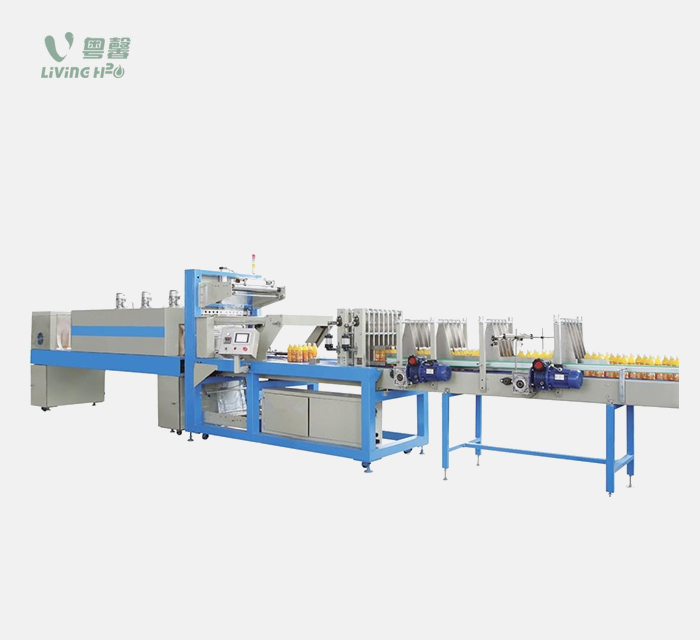

● frequency converter speed adjust、two segment convey device.

● Bottle pushing, thermo sealing and cutting whole movement adopt to pneumatic fracture.

● Proximity switch control film length

● Touch screen, PLC system greatly increase facility movement reliability.

● Three-wind recycle fan machine, ensure shrinkage tunnel inside even temperature.

● Super big wind-volume cooling system, ensure quickly get into shape .

● Anti-high temperature teflon convey belt, convey steadily, high-strength anti-abrasion.

● Frequency limitless speed adjust convey belt frame.

● convey belt height can make according client requirement, adjust range:±100mm

● Wing stainless steel heating system, endurance

● Meet with product instant stop requirement product-bearing rack device ensure production line consistency.

● Overall size: L12000×W1100×H2100mm

Main equipment:3400×1250×2350mm

Shrinkage machine:4200×1100×1700mm

Conveyor: 5200×1300×950mm

● Wrappage max size: L2400×W650×H450mm

● shrinkage film material: PE

●shrinkage film thickenss:0.03-0.15mm

● heating shrinkage tunnel max temperature: 160 - 260° adjust at will

● max output per minute: 20 bag

●total power:25Kw

● actual power:20Kw/h

● pressure requirement: 380V/50-60HZ

● weight: 2500kg

● air pressure: 0.6-0.8mpa

● working noise:≤65db

● import bottle convey belt width: 541mm

● fan:1.1Kw 3set 380V, 60W 6set 380V

PRODUCTS

CONTACT US

For any general inquiries, please fill in the following contact form.

Address:No. 4 Fengyu Road, Pengjiang District, Jiangmen City,Guangdong Province

Mobile / Whatsapp / Wechat:+86-13923086155

Tel:+8613923086155

Email:livingvivy@gmail.com